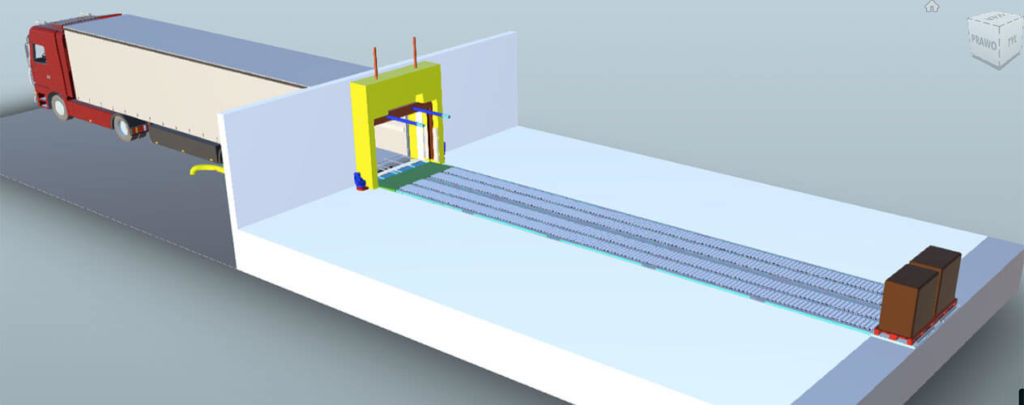

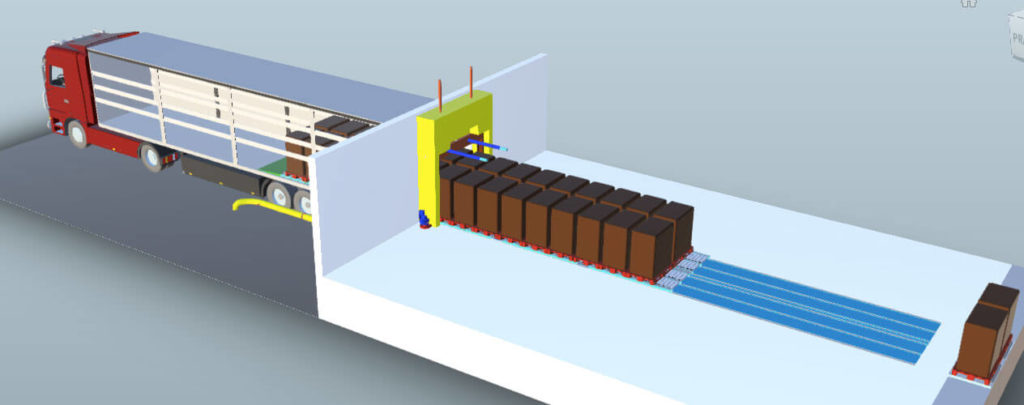

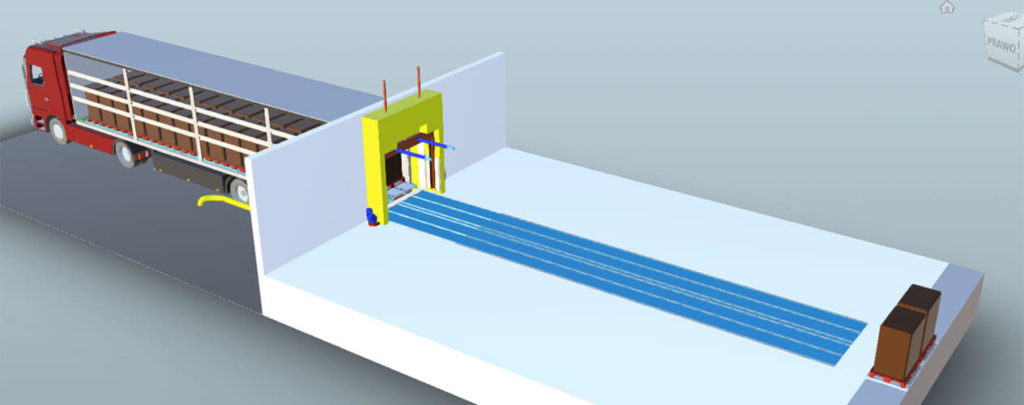

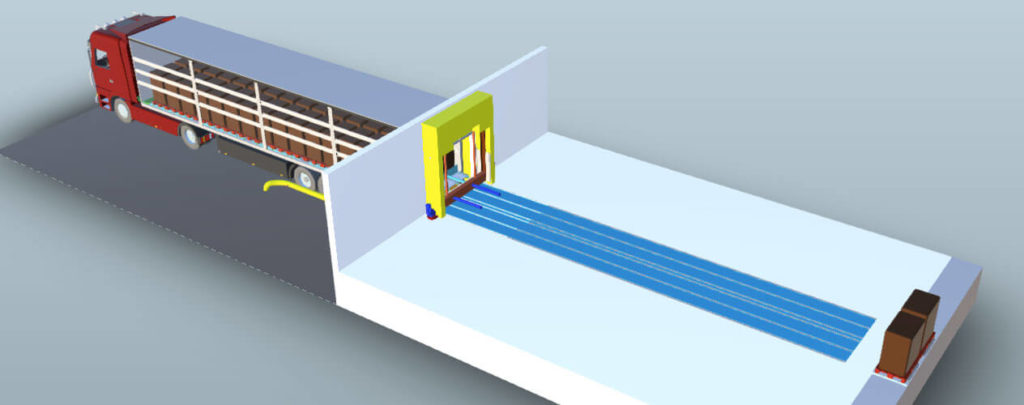

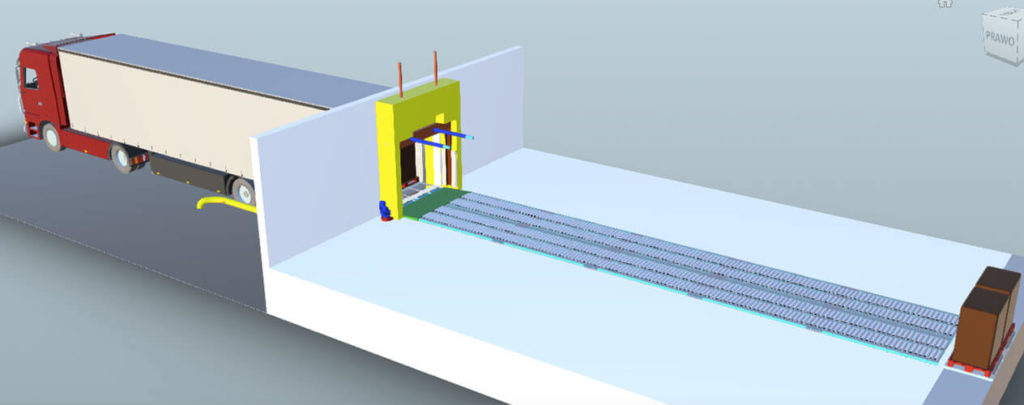

Q Loader allows for the optional use of an automatic storage field.

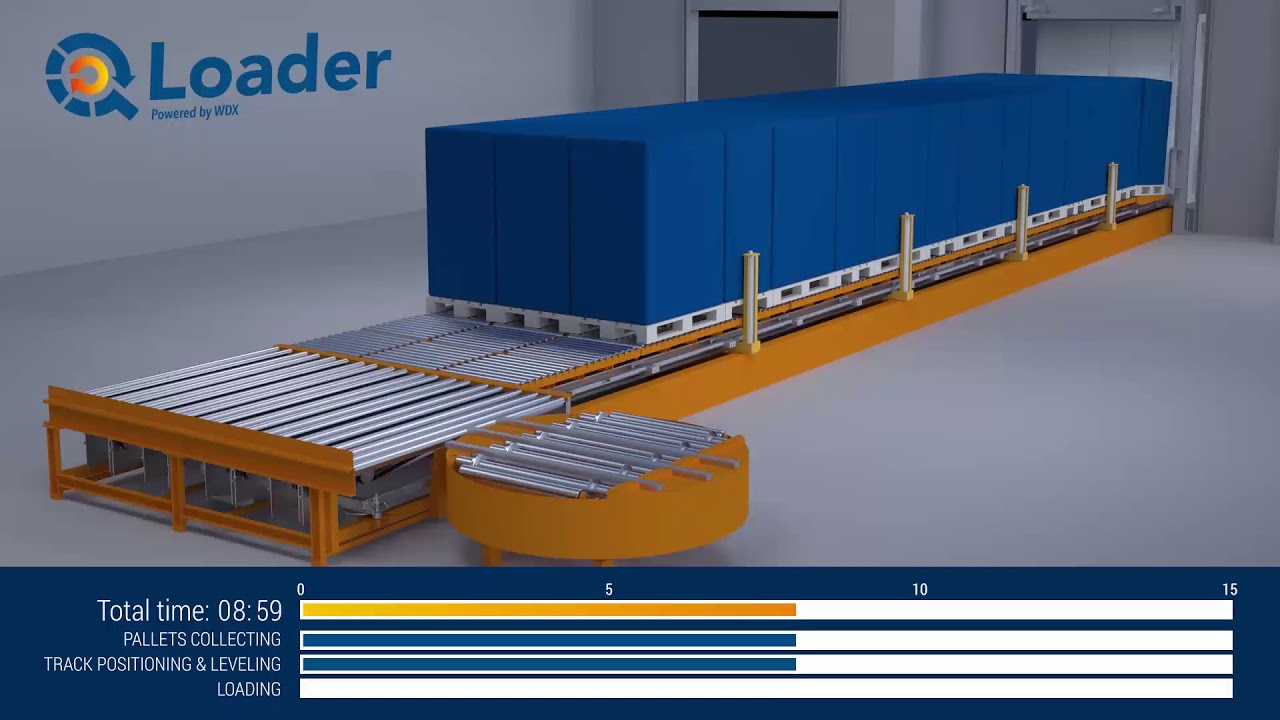

Q Loader can be supplied with palletized goods or via conveyors.

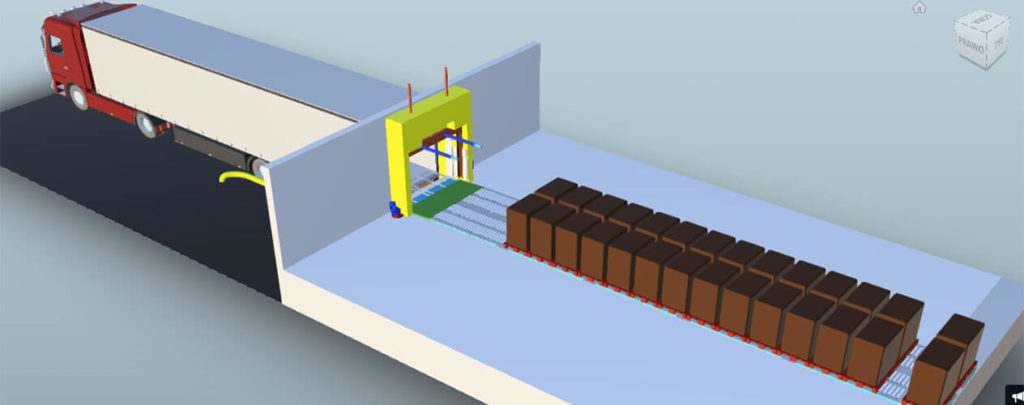

When using the Q Loader, the loads can be on pallets but it is not necessary – the Quick Cargo Loader system can handle cardboard boxes, household appliances, etc.

Q Loader has a system for positioning pallets / loads on the platform – it is impossible to place loads outside the platform area. In addition, the load alignment correction system corrects the load alignment by moving the loads towards each other, i.e. aligning the loads so that they do not protrude beyond the platform contour.

The loads on the Q Loader can be stacked.

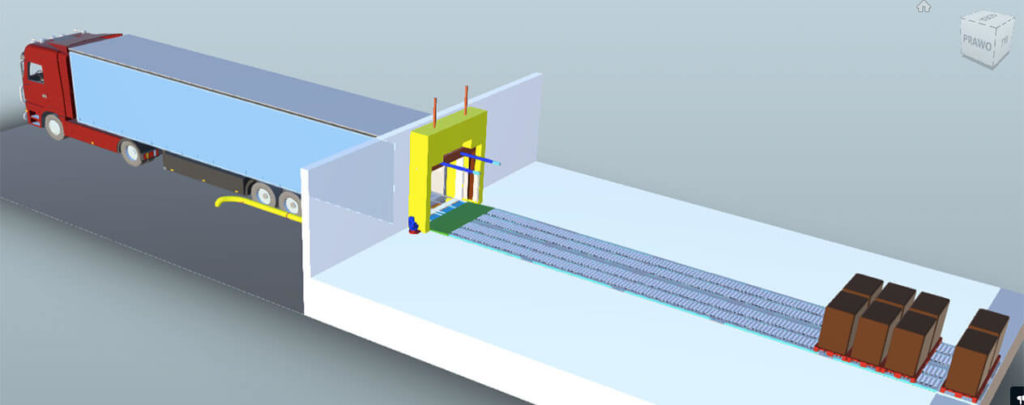

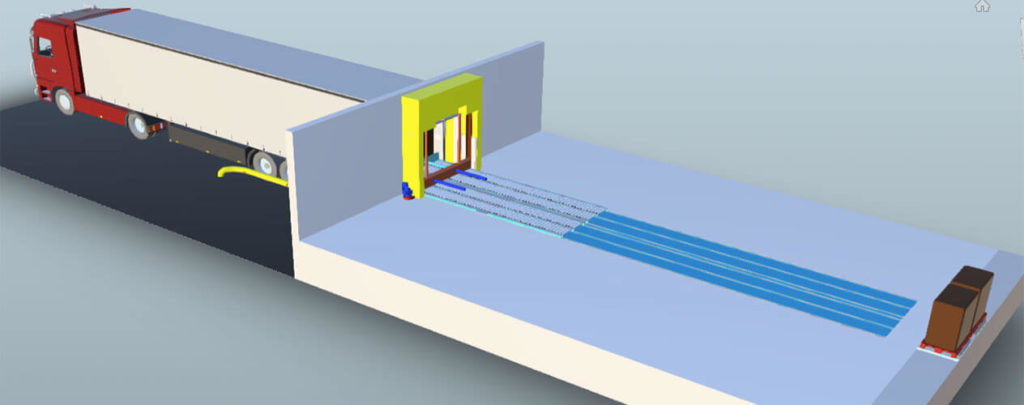

The alignment of the semi-trailer against the loading dock equipped with the Quick Cargo Loader (Q Loader) system takes place during the loading of the platform. The trailer is positioned on a platform that automatically adjusts the floor level of the trailer or container.

A camera system together with A remote control panel enable the driver to align the semi-trailer correctly. The trailer is guided in the same way as with the rear-view camera in cars.

Installation of the Quick Cargo Loader System does not require any construction work – the Q Loader is anchored to the ground.